The Cold Weather Problem

Winter comes.

Your warehouse gets cold.

You open a drum of SLES.

It looks like jelly. Or solid wax.

Your dishwashing liquid turns cloudy.

Your shampoo has white chunks floating in it.

What’s going on?

Why Surfactants Freeze

Surfactants are not pure chemicals.

They’re mixtures of related molecules.

Some of these molecules solidify at low temperatures.

SLES (70%):

Starts getting thick below 15°C.

Below 10°C, it can become paste or solid.

AOS liquid:

Usually more stable in cold.

But can still thicken significantly.

SLS powder:

Not a problem. It’s already solid.

Is Frozen Product Ruined?

Good news: Usually not.

For raw materials (SLES, AOS):

Warm them up gently.

Put the drum in a warm room (25-30°C).

Let it sit for 24-48 hours.

Stir or shake well before using.

The product should return to normal.

Warning:

Don’t heat too fast.

Don’t use open flames.

Gradual warming is best.

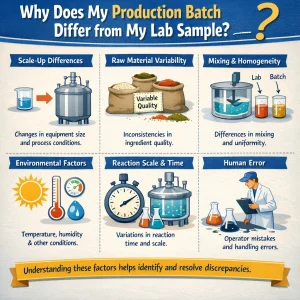

What About Finished Products?

Finished products are trickier.

If your shampoo turns cloudy:

It might recover when warmed.

But sometimes the formula permanently separates.

This is a formulation problem, not a raw material problem.

If chunks appear:

Some ingredients may have crystallized.

Warming might help. Might not.

Prevention is better than cure.

How to Make Cold-Stable Products

Strategy 1: Use solvents.

Adding small amounts of certain solvents lowers the freezing point.

Common options:

- Propylene glycol (1-3%)

- Glycerin (2-5%)

- Ethanol (1-2%)

These are like antifreeze for your product.

Strategy 2: Use hydrotropes.

Hydrotropes help surfactants stay dissolved in cold water.

Common options:

- Sodium xylene sulfonate (SXS)

- Sodium cumene sulfonate (SCS)

- Sodium toluene sulfonate

Add 1-3% to your formula.

Strategy 3: Reduce surfactant concentration.

High-concentration products freeze more easily.

If cold stability is critical, consider a more diluted formula.

Strategy 4: Choose the right SLES.

Some SLES grades are made for cold climates.

Ask your supplier for “low-freeze” or “cold-stable” grades.

These cost more but solve the problem at the source.

AOS: Your Cold Weather Friend

Here’s a useful trick.

AOS has better cold stability than SLES.

Blend them together.

Replace part of your SLES with AOS.

Example: Instead of 15% SLES, use 10% SLES + 5% AOS.

The blend often has better cold tolerance.

Bonus: Also improves hard water performance.

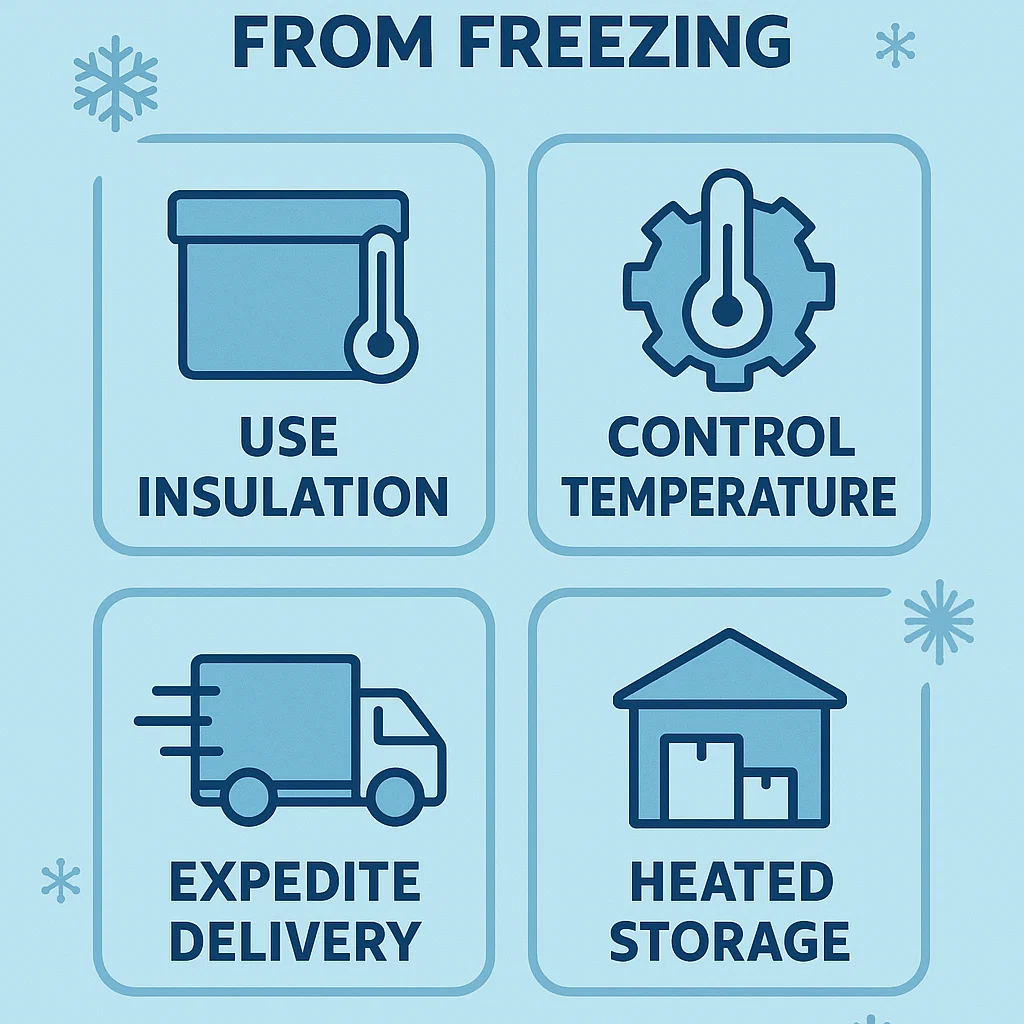

Storage Tips for Cold Months

For raw materials:

Store drums off the concrete floor.

Use pallets. Cold floors make things worse.

If possible, heat your warehouse to above 15°C.

For finished products:

Avoid shipping during extreme cold.

Use insulated packaging if necessary.

Warn your customers about proper storage.

Quick Troubleshooting Guide

| Problem | Likely Cause | Solution |

| SLES turned solid | Normal cold behavior | Warm slowly, stir well |

| Finished product cloudy | Surfactant crystallization | Add hydrotrope or solvent |

| White chunks in shampoo | Ingredient precipitation | Reformulate with glycol |

| Viscosity dropped after freezing | Structure breakdown | Product may be damaged |

The Bottom Line

Cold weather is a formulator’s enemy.

Plan ahead.

Add solvents or hydrotropes to your formula.

Store raw materials properly.

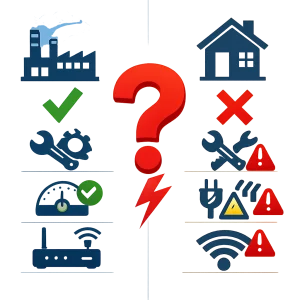

And always test your product’s stability at low temperatures before mass production.