Learning from Failures

In 30 years, I’ve seen it all.

Batches ruined. Money lost. Customers angry.

But every disaster taught me something.

Here are the most common problems and how to fix them.

Problem 1: “My Product Changed Color”

Scenario:

Your clear shampoo turned yellow.

Or your white lotion turned pink.

Possible causes:

- Iron contamination. Very common. Iron reacts with many ingredients.

- UV exposure. Light degrades dyes and some surfactants.

- pH drift. Some colors are pH-sensitive.

- Fragrance reaction. Vanillin in fragrance causes browning.

- Oxidation. Exposure to air over time.

Solutions:

- Add EDTA (0.1%) to chelate iron.

- Use opaque packaging.

- Check pH stability.

- Avoid fragrances with vanillin for light-colored products.

- Add antioxidants if needed.

- Check your water quality. Install filters.

Problem 2: “The Viscosity Changed After Filling”

Scenario:

Product was perfect in the tank.

After filling into bottles, it’s too thin. Or too thick.

Possible causes:

- Air incorporation. Mixing during filling adds air, changes viscosity reading.

- Temperature difference. Product cooled down in bottles.

- Delayed thickening. Some systems take hours to reach final viscosity.

- Salt settling. In some formulas, salt distributes unevenly.

Solutions:

- Let filled bottles rest 24 hours before checking.

- Control filling temperature.

- Do viscosity checks at consistent temperature.

- Ensure complete salt dissolution before filling.

Problem 3: “Customers Say It Smells Funny”

Scenario:

Your fragrance was fine. Now customers complain about the smell.

Possible causes:

- Fragrance degradation. Heat, light, or pH killed the fragrance.

- Base odor breaking through. Surfactants have their own smell. Fragrance not strong enough.

- Microbial contamination. Bacteria create off-odors.

- Chemical reaction. Fragrance reacted with something in the formula.

Solutions:

- Increase fragrance dosage (if budget allows).

- Check storage conditions.

- Improve preservative system.

- Test fragrance stability in your specific formula.

- Choose fragrances designed for your product type.

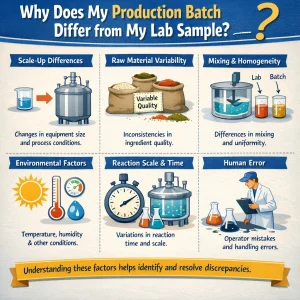

Problem 4: “It’s Not Cleaning Well Anymore”

Scenario:

Same formula. Same ingredients. But customers say cleaning is worse.

Possible causes:

- Surfactant quality changed. Supplier gave you different batch.

- Active matter dropped. You’re not using enough surfactant.

- Water changed. Harder water in customer’s area.

- User expectation changed. Competitor released better product.

Solutions:

- Test incoming raw materials. Check active matter.

- Compare with retained samples from previous batches.

- Ask customer about their water quality.

- Consider reformulation if market has moved on.

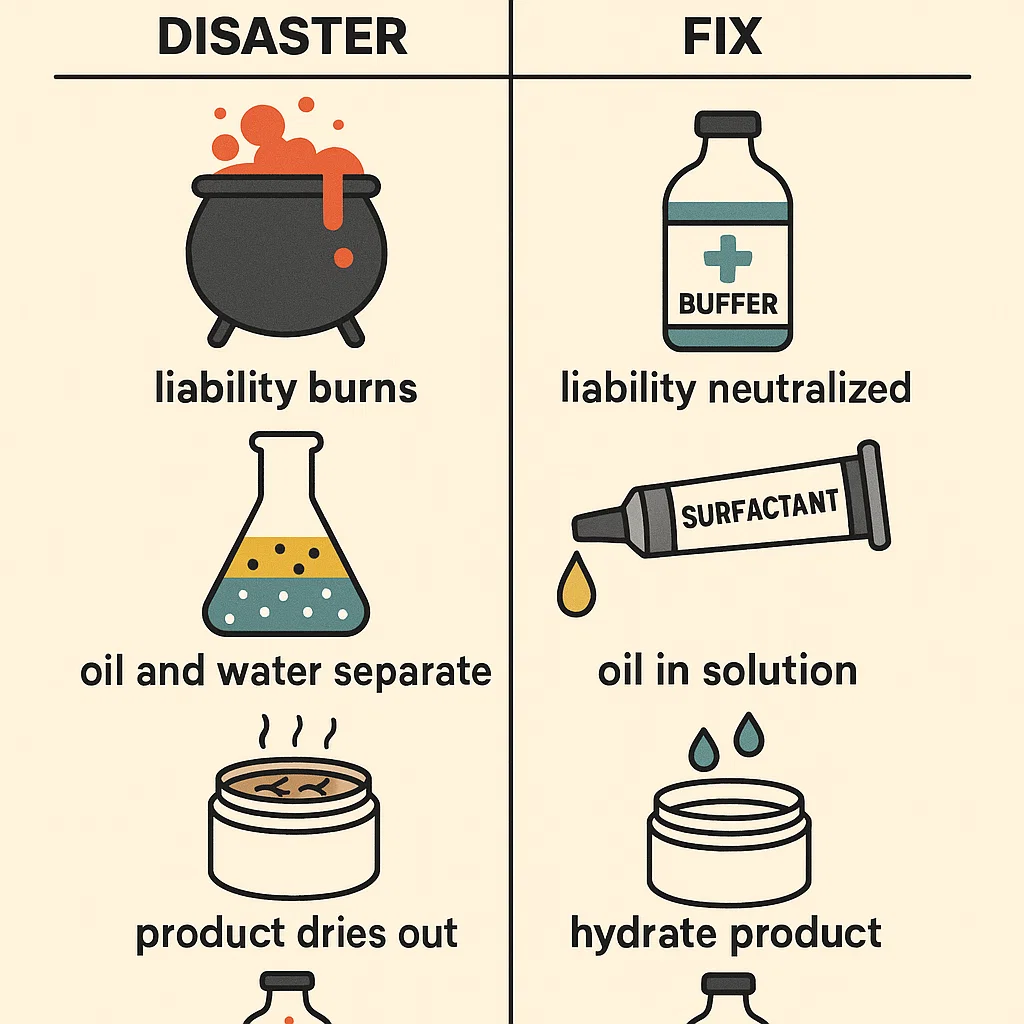

Problem 5: “The pH Won’t Stay Stable”

Scenario:

You adjust pH to 6.0. A week later it’s 5.2. Or 7.5.

Possible causes:

- Microbial activity. Bacteria produce acids.

- Chemical hydrolysis. Some ingredients break down and release acid.

- CO2 absorption. Product absorbs carbon dioxide from air.

- Buffer capacity too low. No resistance to pH change.

Solutions:

- Improve preservative system.

- Use pH buffers (citric acid/sodium citrate system).

- Close containers properly. Minimize air exposure.

- Identify which ingredient is unstable.

Problem 6: “Foam Dies Too Quickly”

Scenario:

Nice initial foam. But it disappears in seconds.

Possible causes:

- Oils killing foam. Added oils or fatty ingredients.

- Fragrance antifoam effect. Some fragrances collapse foam.

- No foam stabilizer. Nothing to reinforce the bubbles.

- Surfactant too diluted. Not enough to maintain foam.

Solutions:

- Add foam stabilizers (CMEA, CAB).

- Test fragrance foam compatibility separately.

- Increase surfactant concentration.

- Reduce oily additives or use foam-compatible versions.

Problem 7: “Pump Bottles Won’t Dispense”

Scenario:

Product is too thick for the pump.

Or pump clogs after a few uses.

Possible causes:

- Viscosity too high. Pump can’t handle it.

- Product crystallizing. Solidifies inside pump tube.

- Particulates. Something in the formula blocks the pump.

- Wrong pump type. Not designed for your product’s viscosity.

Solutions:

- Reduce viscosity.

- Add anti-crystallization agents.

- Filter product before filling.

- Work with packaging supplier to select correct pump.

Problem 8: “Label Is Peeling Off”

Scenario:

Labels fall off bottles during storage or shipping.

Possible causes:

- Surface contamination. Product residue on bottle during labeling.

- Humidity. Moisture gets under the label.

- Bottle material incompatibility. Label glue doesn’t stick to your plastic.

- Product migration. Product seeps through bottle wall (rare).

Solutions:

- Clean bottles before labeling.

- Improve labeling environment (control humidity).

- Test different label adhesives.

- Check bottle material compatibility.

The Troubleshooting Mindset

When problems happen, stay calm.

Ask these questions:

- What changed? New supplier? New ingredient? New equipment?

- When did it start? Find the specific batch.

- Is it consistent? All bottles? Or just some?

- Can you reproduce it? Make a small test batch.

- What do you still have? Keep retained samples from every batch.

The Bottom Line

Problems will happen.

That’s not failure. That’s the job.

The skill is diagnosing quickly and fixing effectively.

Document everything. Learn from every mistake.

After 30 years, I still learn new things from failures.