The Problem

You tested your product.

Works great in your lab.

Works great in your factory.

Ship to customer.

They complain it doesn’t work.

Same product. Different results.

What’s going on?

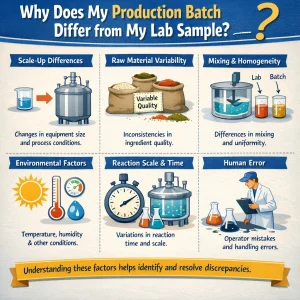

The Usual Suspects

Suspect 1: Water quality difference.

Your water: Soft, clean, consistent.

Their water: Hard, variable, mineral-rich.

Surfactants behave differently.

Suspect 2: Temperature difference.

You tested at 25°C.

They use it at 5°C or 50°C.

Performance changes with temperature.

Suspect 3: Usage method difference.

You tested with proper dilution.

They use it wrong.

Too concentrated. Or too diluted.

Suspect 4: Storage damage.

Product was fine when shipped.

Got too hot or cold during transport.

Or sat in their warehouse too long.

Suspect 5: Expectations mismatch.

Your product works as designed.

They expected something else.

Communication problem.

Diagnosing Water Quality Issues

Water hardness is the biggest variable.

How to check:

Ask customer about their water.

- Municipal supply or well water?

- Any water treatment?

- What’s the hardness level?

Test it yourself:

Get sample of their water.

Test your product in that water.

Do you see the same problem?

Signs of hard water issue:

- Less foam

- Poor lather

- White residue after drying

- “Scummy” feel

Fixing Water Quality Problems

Short term:

Reformulate with more AOS.

AOS handles hard water better.

Or add water softening agents (EDTA, citric acid).

Long term:

Recommend customer install water softener.

Or provide concentrated product with built-in softeners.

Diagnosing Temperature Issues

Get information:

At what temperature do they use product?

How do they store it?

Test accordingly:

Replicate their conditions in your lab.

Test at their temperature.

Test after storage at their conditions.

Fixing Temperature Issues

For cold use:

Add antifreeze agents (glycol, ethanol).

Choose surfactants with better cold performance.

Test cold stability before shipping.

For hot use:

Ensure formula is stable at high temperature.

Some ingredients break down in heat.

Some fragrances evaporate faster.

Diagnosing Usage Method Issues

Ask questions:

- How much product do they use?

- What dilution ratio?

- What application method?

- How long do they let it sit?

- How do they rinse?

Common problems:

- Over-dilution (product too weak)

- Under-dilution (waste, possible residue)

- Wrong application method

- Not enough contact time

Fixing Usage Issues

Provide clear instructions:

Written documentation.

Dilution charts.

Application guidelines.

Training:

For important customers, visit and train their staff.

Show proper technique.

Product labeling:

Clear dosage instructions on package.

Can’t expect them to guess correctly.

When It’s an Expectations Problem

Sometimes the product is fine.

Customer expected something different.

Examples:

- Thought it would be thicker

- Expected more foam

- Wanted different scent

- Assumed it would work on different surfaces

Solution:

Better communication before sale.

Clear product specifications.

Samples before bulk orders.

Honest about what product can and can’t do.

Site Visit Investigation

When problem is serious, go look.

What to observe:

- Their water quality

- Storage conditions

- How they handle and use product

- What they compare you to

- What exactly they don’t like

Often reveals:

The real problem is different from what they described.

In-person observation finds things phone calls miss.

Prevention Strategies

Before shipping to new customer:

- Ask about their conditions (water, temperature, usage)

- Send samples for them to test

- Get feedback before bulk order

- Provide clear usage guidelines

Document everything:

Keep records of every complaint.

Look for patterns.

Fix root causes, not just symptoms.

The Bottom Line

Same product can perform differently in different conditions.

Water quality is the biggest variable.

Temperature and usage method also matter.

Investigate before blaming the product.

Communicate clearly with customers.

Sometimes you need to reformulate for specific conditions.