The Heartbreak of Separation

You made a perfect batch.

Beautiful color. Perfect viscosity. Great foam.

You put it on the shelf.

Two months later, you check.

There’s a layer of water on top. Or oily layer. Or both.

The product has separated.

Your batch is ruined.

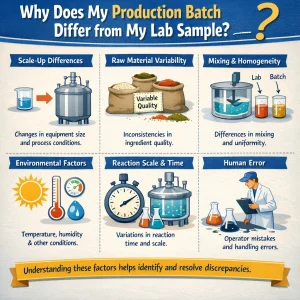

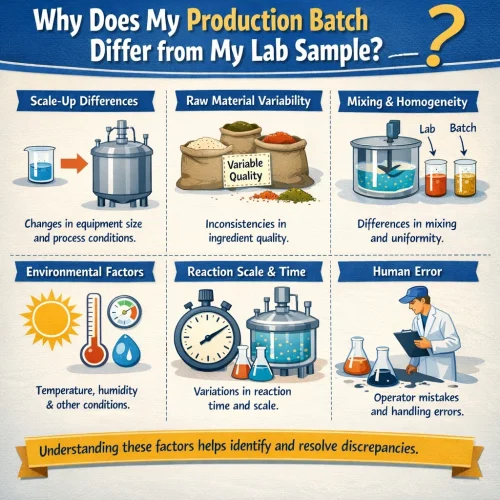

Why Does Separation Happen?

Products are mixtures.

Different ingredients want to separate.

Your job is to stop them.

Main causes of separation:

- Density differences. Heavy ingredients sink. Light ones float.

- Incompatibility. Some ingredients don’t like each other.

- Temperature cycles. Hot/cold changes stress the system.

- Time. Even stable systems eventually fail.

- Microbial contamination. Bacteria break down ingredients.

Type 1: Oil Floating on Top

What you see:

Clear or colored oil layer on surface.

Product underneath looks normal.

Common causes:

- Fragrance oil not properly emulsified.

- Too much fragrance added.

- Fragrance incompatible with surfactant system.

Solutions:

- Use solubilizers (Polysorbate 20, PEG-40 Hydrogenated Castor Oil).

- Reduce fragrance percentage.

- Test fragrance compatibility before production.

- Add fragrance during proper mixing stage.

Type 2: Water Layer on Top

What you see:

Clear water layer separating from thick product below.

Sometimes called “syneresis” or “weeping.”

Common causes:

- Viscosity too low to hold water.

- Thickening system failed.

- Too much water in formula.

- Temperature shock.

Solutions:

- Check salt level. Might need adjustment.

- Add co-thickeners (CMEA, betaine).

- Consider polymer thickener for stubborn cases.

- Improve mixing process.

Type 3: Cloudiness or Haze

What you see:

Product was clear. Now it’s milky or hazy.

Common causes:

- Ingredient crystallization.

- Cold temperature exposure.

- Incompatible additives.

- Microbial growth.

Solutions:

- Check for cold damage. Warm and see if it clears.

- Add hydrotropes (SXS) for better solubility.

- Review all ingredients for compatibility.

- Check preservative system.

Type 4: Chunks or Particles

What you see:

White or colored particles floating or settled.

Common causes:

- Undissolved ingredients.

- Crystallization of surfactant.

- Precipitation of additives.

- Microbial colonies (worst case).

Solutions:

- Ensure complete dissolution during manufacturing.

- Filter product before packaging.

- Add solvents to prevent crystallization.

- Improve preservative if microbial.

Prevention: The Stability Test Protocol

Before you manufacture 1000kg, test 1kg.

Accelerated stability test:

Put samples at three temperatures:

- Room temperature (25°C)

- Elevated temperature (40°C or 45°C)

- Refrigerator (4°C)

Check at intervals:

- 24 hours

- 1 week

- 2 weeks

- 4 weeks

What to look for:

- Color change

- Smell change

- Viscosity change

- Separation

- Clarity change

- pH change

Rule of thumb:

4 weeks at 40°C ≈ 1 year at room temperature.

If it survives the test, it will probably survive real life.

The Importance of Mixing Order

This is overlooked too often.

Order matters.

Adding ingredients in wrong order causes instability.

General principle:

- Start with water.

- Add main surfactants.

- Mix until uniform.

- Add thickeners/boosters.

- Mix well.

- Adjust pH if needed.

- Add salt for viscosity.

- Add preservatives.

- Add fragrance last.

- Add color last.

- Final mixing.

Why fragrance last?

Fragrance is often the least stable component.

Minimize its exposure to processing stress.

Common Mixing Mistakes

Mistake 1: Mixing too fast.

Creates air bubbles.

Bubbles can cause later separation or foam collapse.

Mistake 2: Mixing too slow.

Ingredients don’t disperse properly.

Leads to uneven product.

Mistake 3: Wrong temperature.

Some ingredients need warm water to dissolve.

Others are damaged by heat.

Know your ingredients.

Mistake 4: Adding everything at once.

Worst practice.

Always add ingredients in sequence.

Emergency Fixes

Sometimes separation happens anyway.

Can it be saved?

Sometimes yes. Sometimes no.

Try this:

- Heat gently to 40-50°C.

- Mix thoroughly.

- Cool slowly while mixing.

- Check if it’s stable again.

If oil separated:

Add more solubilizer.

Mix vigorously.

If it keeps separating:

The formula is fundamentally unstable.

No amount of mixing will fix it.

You need to reformulate.

The Bottom Line

Stability is not luck. It’s science.

Test before mass production.

Follow proper mixing procedures.

Understand why separation happens.

Prevention is always easier than cure.