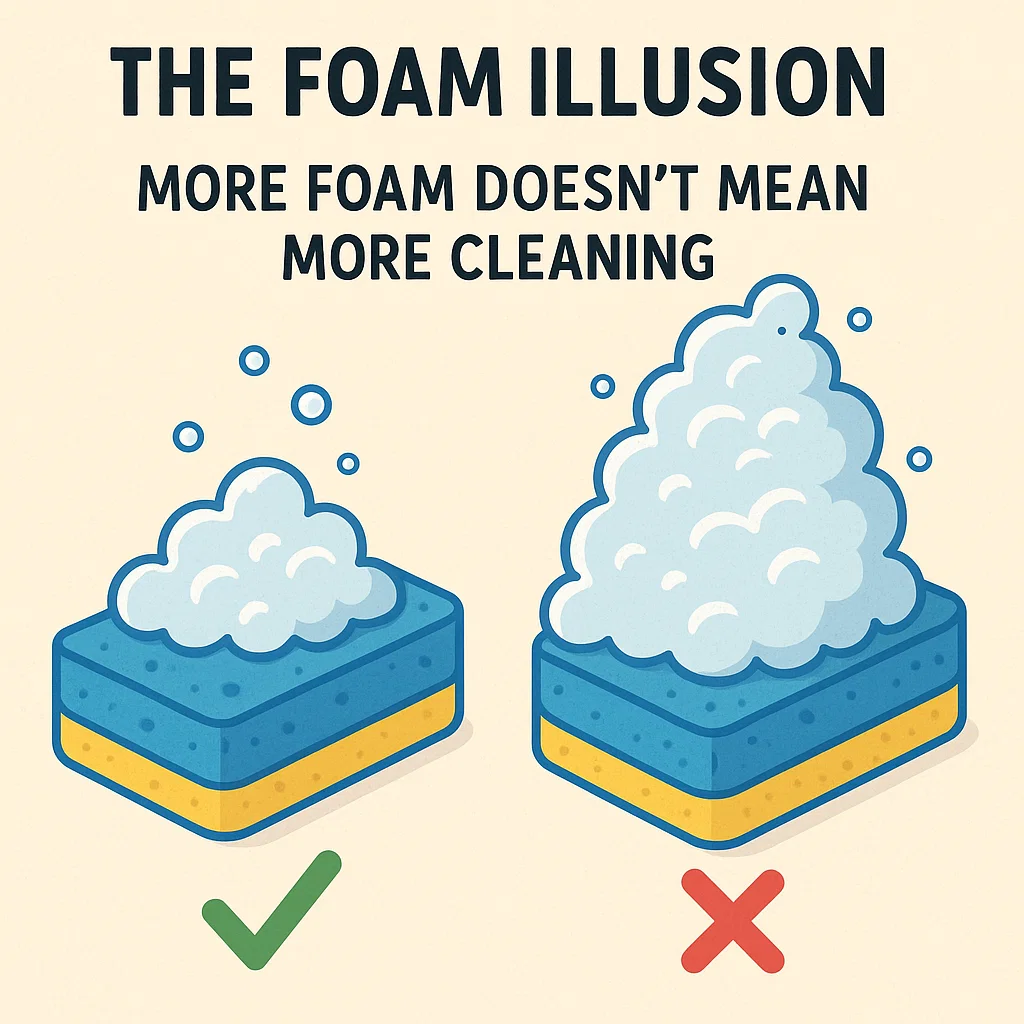

The Customer Perception Problem

Your customer says:

“Your product doesn’t foam enough. It doesn’t clean well.”

You know the truth.

Foam and cleaning power are NOT the same thing.

But customers don’t believe it.

What do you do?

The Science of Cleaning

Let’s be clear about how surfactants actually work.

Cleaning happens in four steps:

- Wetting: Surfactant helps water spread over the dirty surface.

- Lifting: Surfactant molecules get under the dirt and oil.

- Emulsifying: Dirt and oil break into tiny droplets.

- Suspending: Droplets stay suspended in water so they can be rinsed away.

Notice something?

Foam is not mentioned anywhere.

Foam is a side effect, not the cause of cleaning.

Why Do Customers Love Foam?

Psychology.

Foam is visible. Cleaning is invisible.

When people see big bubbles, they feel something is happening.

No foam = no action (in their minds).

This is especially true for:

- Dishwashing liquid

- Hand soap

- Shampoo

- Car wash

Two Types of Foam

Not all foam is equal.

Type 1: Big, fluffy foam.

Large bubbles. Impressive looking.

But weak. Collapses quickly.

Often called “flash foam.”

Type 2: Dense, creamy foam.

Small bubbles. Compact.

Lasts longer. Feels richer.

Called “stable foam” or “creamy lather.”

How to Create “Show Foam” (The Visual Trick)

Sometimes you need foam for marketing, not for cleaning.

Trick 1: Add foam boosters.

CMEA (Cocamide MEA) increases foam volume dramatically.

CAB/CAPB makes foam more stable and creamy.

Trick 2: Adjust the surfactant ratio.

AOS produces denser foam than SLES.

Blend them for best visual effect.

Trick 3: Consider foam stabilizers.

Lauramide DEA was popular (but has safety concerns now).

CMEA is a safer alternative.

Trick 4: Reduce antifoam contaminants.

Oils and silicones kill foam.

Make sure your fragrance oils are compatible.

Some cheap fragrances destroy foam.

When You DON’T Want Foam

Some applications need low foam.

Automatic dishwashers:

Foam interferes with the machine.

Too much foam = poor results.

Industrial cleaning:

Foam makes rinsing difficult.

Can overflow from tanks.

Laundry machines (HE type):

High-efficiency washers use less water.

Excess foam is a problem.

What to do:

Choose low-foam surfactants.

Or add antifoaming agents (silicone-based or alcohol-based).

Foam Testing for Quality Control

How to measure foam objectively.

Simple method: Ross-Miles test.

Pour surfactant solution from fixed height.

Measure foam height immediately.

Measure again after 5 minutes.

What to look for:

Initial height = foam generation ability.

Height after 5 min = foam stability.

Good products have both.

Educating Your Customers

Here’s how I explain it to non-technical buyers.

“Think about washing your hands with oil on them.

You put soap on. You rub.

Where did the foam go? The oil killed it.

But when you rinse, hands are clean.

The soap worked even though foam was low.

Foam is the advertisement. Cleaning is the real product.”

Some customers will understand.

Some won’t. That’s okay.

For the stubborn ones, just give them more foam.

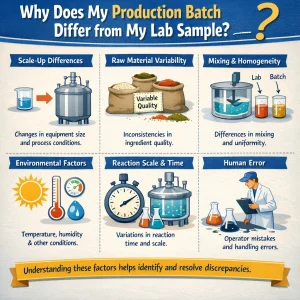

Formula Example: High-Foam Dishwashing Liquid

Goal: Maximum visual foam, decent cleaning.

| Ingredient | Percentage |

| SLES (70%) | 12% |

| AOS (35%) | 4% |

| CMEA | 2.5% |

| CAB (30%) | 3% |

| Salt | To desired viscosity |

| Preservative | 0.2% |

| Fragrance | 0.3% |

| Color | As needed |

| Water | To 100% |

This formula will foam impressively.

And yes, it also cleans.

The Bottom Line

Foam is marketing.

Cleaning is chemistry.

They overlap, but they’re not the same.

Give customers what they want to see.

But know the truth behind the bubbles.