The Most Common Frustration

You’re making dishwashing liquid.

You add SLES. You add salt to thicken it.

It gets thicker. Good.

You add more salt. Even thicker. Great.

You add a bit more salt… and suddenly it’s water again.

What happened?

Understanding the Salt Curve

Salt thickening doesn’t work in a straight line.

It follows a curve. Like a hill.

Stage 1: Going up the hill.

You add salt. Viscosity increases.

The product gets thicker.

Stage 2: At the top.

Maximum thickness achieved.

This is your sweet spot.

Stage 3: Going down the hill.

You add more salt. Viscosity drops.

Sometimes dramatically.

Your thick gel becomes watery soup.

Why Does This Happen?

Let me explain simply.

Surfactant molecules form tiny structures in water.

These structures are called micelles.

Salt affects how micelles arrange themselves.

At the right salt level:

Micelles connect and form networks.

The network makes the liquid thick.

Too much salt:

The network breaks apart.

Micelles become small and separate.

Thickness disappears.

How to Find Your Sweet Spot

Step 1: Start with a test batch.

Make 500g of your product without thickener.

Step 2: Add salt slowly.

Add 0.5% salt (based on total weight).

Mix well. Check viscosity.

Record the result.

Step 3: Keep adding.

Add another 0.5%.

Mix. Check. Record.

Repeat until viscosity starts dropping.

Step 4: Find the peak.

Your sweet spot is just before the drop.

Usually between 1-4% salt for SLES systems.

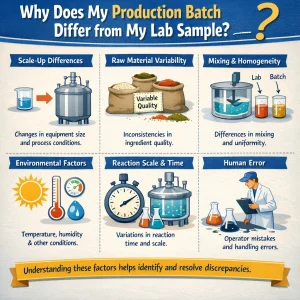

Different Surfactants, Different Behavior

Not all surfactants thicken the same way with salt.

SLES:

Very responsive to salt.

Easy to thicken.

Most forgiving if you make small mistakes.

SLS:

Also responds to salt.

But needs to be dissolved first (if using powder).

AOS:

Stubborn.

Salt alone doesn’t work well.

Needs co-thickeners (more on this below).

Blends:

When you mix surfactants, the salt curve changes.

Always test your specific formula.

What If Salt Doesn’t Work?

Sometimes salt isn’t enough.

Maybe you need higher viscosity.

Maybe your formula contains ingredients that fight thickening.

Alternative thickeners:

- CMEA (Cocamide MEA): Boosts foam and helps thickening.

- Betaine (CAB): Adds mildness and helps viscosity.

- CAPB (Cocamidopropyl Betaine): Similar to CAB.

For really thick products:

Consider adding small amounts of:

- Hydroxyethyl cellulose (HEC)

- Carbomer

But these cost more. Use only when needed.

Common Mistakes to Avoid

Mistake 1: Adding salt too fast.

Salt needs time to dissolve and interact.

Add slowly. Mix for 2-3 minutes between additions.

Mistake 2: Using wrong type of salt.

Use sodium chloride (NaCl). Regular salt.

Don’t use iodized table salt. The additives cause problems.

Mistake 3: Not accounting for other ingredients.

Fragrance oils, preservatives, and colorants can affect viscosity.

Add them before doing final salt adjustment.

Mistake 4: Temperature matters.

Viscosity changes with temperature.

Test at the temperature your product will be stored at.

A Real-World Example

Product: Dishwashing liquid

Base formula:

- SLES (70%) – 15%

- AOS (35%) – 5%

- CMEA – 2%

- Water – to 100%

Salt thickening test results:

| Salt % | Viscosity (cps) |

| 0.5% | 200 |

| 1.0% | 800 |

| 1.5% | 2,500 |

| 2.0% | 4,000 |

| 2.5% | 3,200 |

| 3.0% | 1,500 |

Sweet spot: 2.0% salt.

Going to 2.5% already starts the decline.

The Bottom Line

Salt thickening is cheap and effective.

But it has limits.

Learn to find your peak.

When salt fails, use co-surfactants or polymer thickeners.

Always test in small batches first.