The Problem

You developed a formula in the lab.

Perfect. Tested. Approved.

Scale up to production.

1000 kg batch doesn’t match 1 kg sample.

Viscosity different. Color different. Performance different.

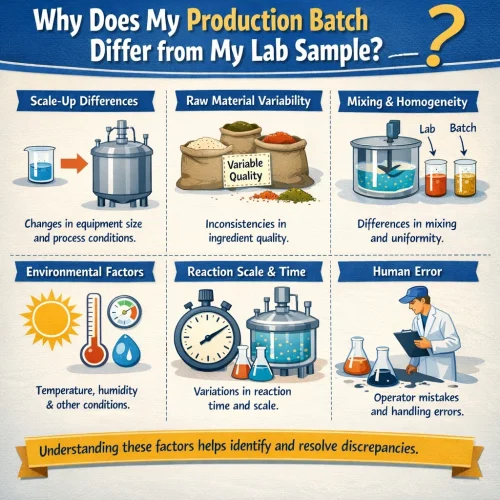

Why?

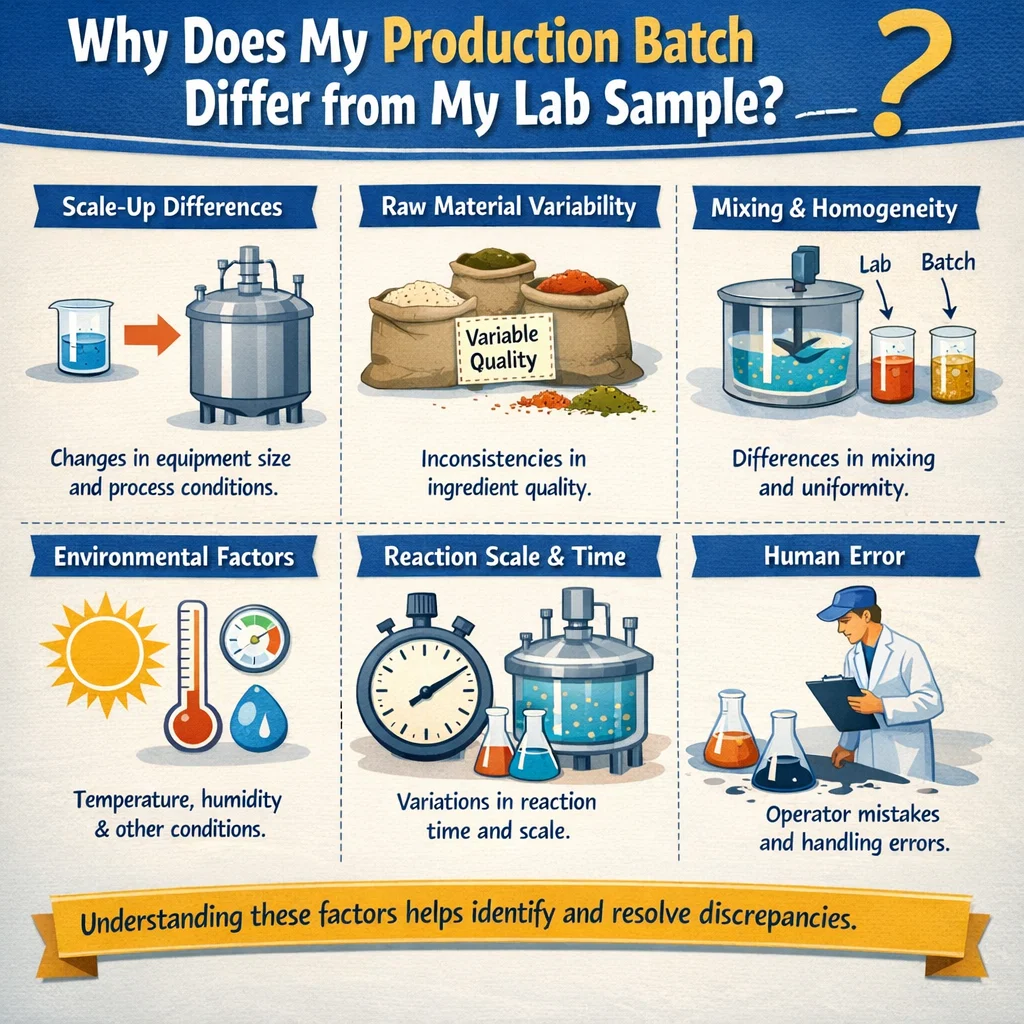

Scale-Up Is Not Just Multiplication

Making 1000x more product is not just multiplying ingredients.

The process changes.

Physics changes.

Results change.

Common Scale-Up Issues

Issue 1: Mixing efficiency.

Lab: Small beaker, high-speed stirrer.

Every molecule gets mixed quickly.

Production: Large tank, different mixer.

Mixing is less uniform.

Dead spots exist.

Issue 2: Heat management.

Lab: Small batch cools quickly.

Temperature easy to control.

Production: Large batch retains heat.

May get hotter than intended.

Heat affects reactions and stability.

Issue 3: Addition rates.

Lab: Add ingredient drop by drop.

Perfect control.

Production: Add by pump or pouring.

Much faster. Less controlled.

Some reactions need slow addition.

Issue 4: Ingredient quality variations.

Lab: Use samples from one batch.

Production: Use bulk from different batches.

Batch-to-batch variation affects results.

Issue 5: Water source.

Lab: May use purified water.

Production: Use tap or plant water.

Minerals and impurities differ.

Issue 6: Equipment materials.

Lab: Glass or stainless steel.

Production: May have different metals.

Metal contact can cause reactions.

Iron contamination causes color issues.

Prevention: Scale-Up Protocols

Protocol 1: Intermediate testing.

Before 1000 kg, make 50 kg trial batch.

Use production equipment.

Identify problems at smaller scale.

Cheaper to waste 50 kg than 1000 kg.

Protocol 2: Match mixing conditions.

Calculate equivalent mixing energy.

Different tank size needs different mixer settings.

Consult with equipment supplier.

Protocol 3: Control temperature.

Monitor temperature during production.

Add cooling if batch gets too hot.

Slow down if needed.

Protocol 4: Test all ingredient batches.

Before production, test each raw material lot.

Compare to lab sample materials.

Identify any differences.

Protocol 5: Use same water source.

If lab uses special water, use same in production.

Or adjust formula for production water quality.

Documenting Lab Procedures

When developing in lab, record everything.

Critical details:

- Exact order of addition

- Mixing speed at each step

- Mixing time at each step

- Temperature at each step

- When to measure pH

- When to check viscosity

- Hold times between steps

- Total process time

Without this, production team is guessing.

The Production Batch Record

Create detailed procedure:

Not just ingredient list.

Step-by-step instructions.

Include checkpoints and quality tests.

Example format:

| Step | Action | Time | Temperature | Mixing Speed | Checkpoint |

| 1 | Add water to tank | – | 25°C | Off | – |

| 2 | Start mixer | – | – | Low | – |

| 3 | Add SLES slowly | 10 min | 25-30°C | Low | – |

| 4 | Mix until uniform | 15 min | 25-30°C | Medium | Visual check: no lumps |

| 5 | Add CMEA | 5 min | 25-30°C | Medium | – |

| … | … | … | … | … | … |

Troubleshooting Specific Problems

Viscosity too low in production:

- Check salt addition carefully

- Verify surfactant concentration

- Check mixing time – may need longer

- Temperature might be too high

Viscosity too high in production:

- Reduce salt slightly

- Check for contamination

- Verify water amount

Color darker in production:

- Check for iron in water or equipment

- Verify temperature didn’t spike

- Check raw material quality

Foam different in production:

- Verify ingredient ratios

- Check for contamination

- Test water quality

pH different in production:

- Verify buffer addition

- Check water pH

- Test raw material pH

When to Reformulate vs. Fix Process

Fix the process if:

- Lab sample can be replicated with better controls

- Problem is clearly procedural

- Raw materials test the same

Reformulate if:

- Production conditions can’t match lab

- Water quality is permanently different

- Equipment limitations require formula change

Sometimes you need a “production formula” that differs from “lab formula.”

This is normal for complex products.

The Bottom Line

Scale-up problems are normal.

They don’t mean your formula is bad.

Document lab procedures completely.

Test at intermediate scale.

Control critical parameters.

Investigate differences systematically.

Success comes from patience and attention to detail.