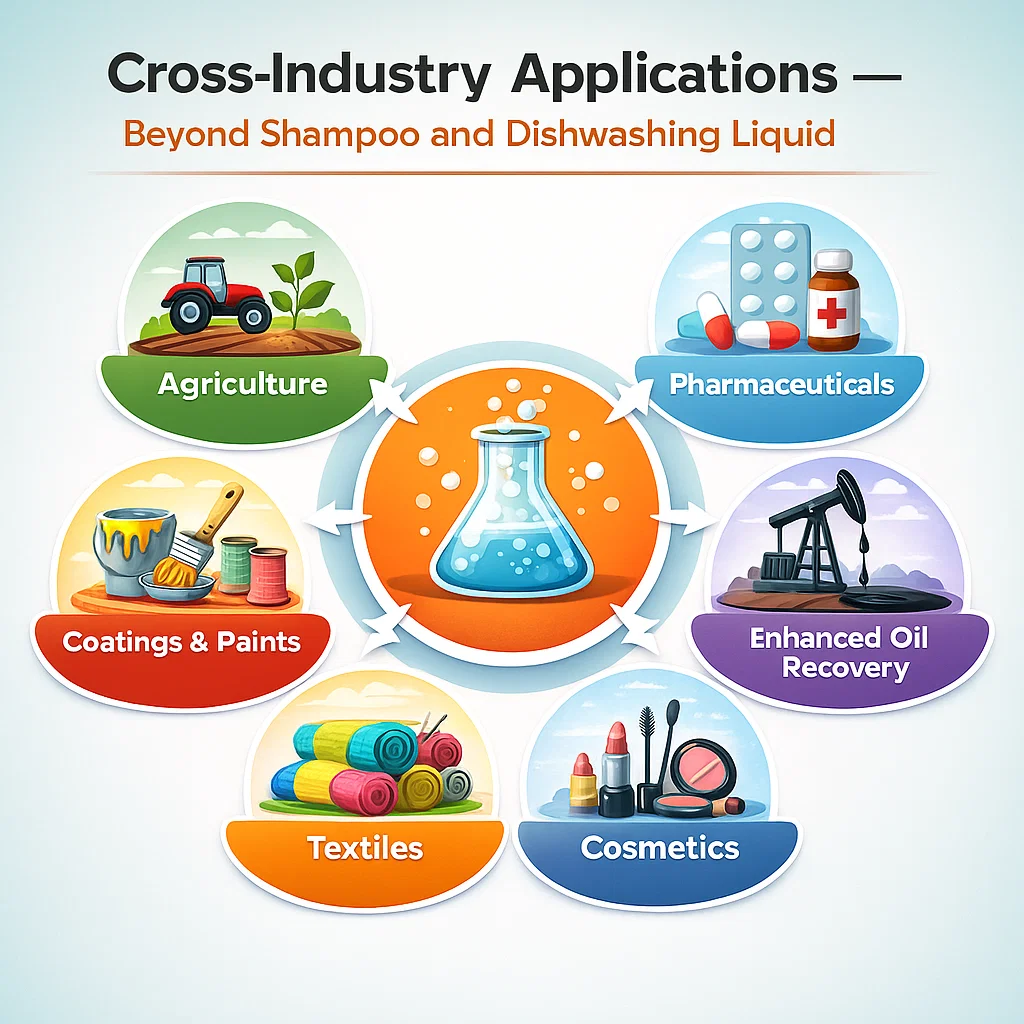

Surfactants Are Everywhere

Most people think of surfactants as “soap ingredients.”

But they go much further.

Let me show you where else these products work.

Construction Industry

Foamed concrete and lightweight blocks.

SLS/K12 is added to cement slurry.

It creates millions of tiny air bubbles.

Result: Lighter concrete. Better insulation.

Key requirements:

- Fast foaming

- Stable bubbles that don’t collapse before cement sets

- Consistent quality (construction is strict)

What to watch:

Construction customers care less about mildness.

They care about foam stability and price.

Gypsum Board Manufacturing

Creating the foam layer.

Gypsum boards (drywall) sometimes need foamed cores.

SLS creates the foam.

Similar to concrete foaming.

Technical note:

Gypsum is alkaline.

Surfactant must be stable at high pH.

Textile Industry

Washing and dyeing fabrics.

Surfactants remove oils from raw fabrics.

They help dyes penetrate evenly.

What’s different:

High-temperature stability matters.

Textile processes run at 60-90°C sometimes.

Low-foam versions often preferred.

Common surfactants:

SLES, AOS, and specialty products for specific fabrics.

Agriculture

Pesticide formulations.

Surfactants help pesticides spread on plant leaves.

Without surfactants, water beads up and rolls off.

With surfactants, it forms a thin film that sticks.

What’s important:

Must not harm plants.

Must be approved for agricultural use.

Environmental safety matters here.

Oil and Gas Industry

Enhanced oil recovery.

Surfactants reduce the tension between oil and rock.

This helps push more oil out of underground reservoirs.

Drilling fluids.

Surfactants control foam and clean the drilling equipment.

Key factor:

Must work under extreme conditions.

High pressure. High temperature. High salinity.

This is specialty territory. Premium prices.

Metalworking and Manufacturing

Cutting fluids and coolants.

When machines cut metal, they generate heat.

Fluids cool the process and wash away metal chips.

Surfactants in these fluids help with:

- Emulsifying oils

- Wetting the metal surface

- Controlling foam

Industrial cleaners.

Removing grease from metal parts before painting or coating.

SLS and SLES are common here.

Fire Fighting

Foam concentrates.

Some fire-fighting foams use surfactants.

The foam smothers fires by cutting off oxygen.

What’s special:

Must produce huge amounts of stable foam.

Must work with seawater or hard water.

AOS is sometimes used in these applications.

Leather Industry

Degreasing hides.

Animal hides have natural fats.

Before tanning, fats must be removed.

Surfactants do this job.

Leather cleaning products.

Similar to fabric care, but for leather goods.

Food Industry (Indirect)

Surfactants don’t go in food.

But they clean the equipment that makes food.

CIP (Clean-in-Place) systems.

Food factories clean tanks and pipes without disassembling.

Surfactant-based cleaners are pumped through.

Requirements:

Must rinse completely.

No residue that could contaminate food.

Often need to meet food-safety certifications.

What This Means for Traders

If you only sell to shampoo factories, you’re missing opportunities.

Expand your customer base:

- Construction companies

- Textile mills

- Industrial cleaning suppliers

- Agricultural chemical companies

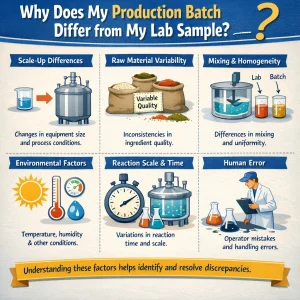

Different customers, different needs:

Personal care → Mildness and foam quality.

Industrial → Performance and price.

Construction → Foam stability and consistency.

Agriculture → Spreading ability and safety.

Adjusting Your Approach

When you talk to industrial customers, speak their language.

Don’t talk about “luxurious lather.”

Talk about:

- Active matter content

- Foam density and stability

- Temperature tolerance

- pH range

- Price per active kilogram

The Bottom Line

Surfactants touch almost every industry.

Learn the applications beyond personal care.

Each industry has specific needs.

Meeting those needs opens new markets.